The Future of Concrete Cutting Technology in Jacksonville

Table of Contents

- Introduction

- Advancements in Concrete Cutting Technology

- Impact on Future Projects in Jacksonville

- Conclusion

Introduction

If you are a homeowner or a business owner in Jacksonville, Florida, you might have encountered the need for concrete cutting at some point. Whether you want to renovate your home, expand your office space, or install new plumbing or electrical systems, concrete cutting is a vital service that can help you achieve your goals.

But what is concrete cutting and how does it work? Concrete cutting is the process of cutting through concrete structures using specialized tools and techniques. It can be used for various purposes, such as:

- Creating openings for doors, windows, vents, or skylights

- Removing damaged or unwanted concrete sections

- Installing utilities such as pipes, wires, or cables

- Demolishing or dismantling concrete structures

- Creating decorative or artistic features on concrete surfaces

Concrete cutting is not a simple task that anyone can do. It requires skill, experience, and the right equipment to ensure a safe and successful outcome. That’s why you need to hire a professional concrete cutting company that can handle any project, no matter how big or small, with efficiency and precision.

At Urban Edge Concrete, we have been providing quality concrete cutting services to our clients for over 20 years. We have the latest technology and the most qualified team to handle any concrete cutting challenge. We are proud to serve the Jacksonville community and help you with your concrete cutting needs.

Advancements in Concrete Cutting Technology

Concrete cutting is a dynamic and evolving industry that constantly adopts new technologies and innovations to improve its performance and quality. In this section, we will highlight some of the emerging technologies in concrete cutting and how they can benefit your projects in Jacksonville.

Diamond Wire Cutting

One of the most significant advancements in concrete cutting technology is the use of diamond wire. Diamond wire cutting is a method that uses a wire embedded with diamond beads to cut through concrete. The wire is attached to a pulley system that moves it along the desired cutting path.

Diamond wire cutting offers several advantages over conventional methods, such as:

- High precision: Diamond wire cutting can create accurate and smooth cuts in any direction, even in curved or irregular shapes. It can also cut through any thickness of concrete, from a few inches to several feet.

- Low noise and vibration: Diamond wire cutting produces minimal noise and vibration, which reduces the impact on the surrounding environment and the workers. It also prevents cracking or chipping of the concrete, resulting in a cleaner and more aesthetic finish.

- Versatility: Diamond wire cutting can be used for a variety of projects, such as bridge demolition, nuclear decommissioning, underwater cutting, or historical preservation.

At Urban Edge Concrete, we have the expertise and the equipment to perform diamond wire cutting for any project. We can handle complex and challenging cuts with ease and efficiency. We can also customize our diamond wire cutting solutions to meet your specific needs and preferences.

Robotic Concrete Cutting

Another advancement in concrete cutting technology is the use of robotic concrete cutting. Robotic concrete cutting is a method that involves the use of automated machines equipped with diamond blades to cut through concrete. These machines can be remotely operated by a human operator, who can monitor and control the cutting process from a safe distance.

Robotic concrete cutting has several benefits over traditional methods, such as:

- Efficiency: Robotic concrete cutting can perform faster and more consistently than manual cutting methods, reducing the time and cost of the project. It can also cut through multiple layers of concrete, steel, or other materials with ease.

- Safety: Robotic concrete cutting improves safety by reducing the need for human labor and exposure to hazards such as dust, noise, or flying debris. It also eliminates the risk of injuries or accidents associated with manual cutting methods.

- Flexibility: Robotic concrete cutting can adapt to different project requirements and site conditions, such as confined spaces, uneven surfaces, or complex shapes. It can also be customized to suit different cutting specifications and preferences.

At Urban Edge Concrete, we have the experience and the technology to perform robotic concrete cutting for any project. We have a fleet of state-of-the-art robotic machines that can handle any concrete cutting challenge. We also have a team of trained and certified operators who can ensure a smooth and safe cutting process.

Laser-guided Concrete Cutting

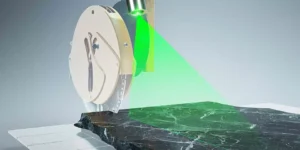

A third advancement in concrete cutting technology is the use of laser-guided concrete cutting. Laser-guided concrete cutting is a method that utilizes laser technology to guide the cutting process. The laser creates a precise cutting path on the concrete surface, which is then followed by a diamond blade or a wire.

Laser-guided concrete cutting offers several advantages over conventional methods, such as:

- Accuracy: Laser-guided concrete cutting ensures accuracy and precision by creating a clear and exact cutting path, reducing the chances of errors or deviations. It can also create intricate cuts or custom shapes that are difficult to achieve with other methods.

- Quality: Laser-guided concrete cutting improves quality by creating smooth and clean cuts, minimizing the need for finishing or polishing. It also preserves the integrity and strength of the concrete, preventing cracking or weakening.

- Sustainability: Laser-guided concrete cutting enhances sustainability by reducing the amount of waste and emissions generated by the cutting process. It also consumes less energy and water than other methods, lowering the environmental impact of the project.

At Urban Edge Concrete, we have the expertise and the technology to perform laser-guided concrete cutting for any project. We have the latest laser equipment and the most skilled technicians who can deliver high-quality and accurate cuts. We can also provide you with a free estimate and a consultation for your laser-guided concrete cutting project.

Impact on Future Projects in Jacksonville

The advancements in concrete cutting technology have several implications for future projects in Jacksonville.

1. Increased Efficiency: The use of advanced technology in concrete cutting enables faster and more efficient project completion. With robotic machines and diamond wire cutting, contractors can achieve precise cuts in less time, reducing overall project timelines.

2. Improved Safety: Safety is a top priority in the construction industry. The introduction of robotic and laser-guided cutting methods reduces the risk of accidents and injuries associated with manual cutting. This improvement in safety measures ensures a safer working environment for construction workers in Jacksonville.

3. Enhanced Precision: The use of diamond wire and laser-guided cutting methods allows for greater precision in concrete cutting. This precision is crucial for projects that require accurate measurements and intricate cuts. The ability to achieve precise cuts ensures the structural integrity of the building and reduces the need for additional repairs or modifications.

4. Cost Savings: While advanced concrete cutting technology may require an initial investment, it can result in long-term cost savings. The increased efficiency and precision of these methods reduce the need for rework and minimize material wastage. Additionally, the use of robotic machines reduces labor costs, making projects more financially viable.

Conclusion

As technology continues to advance, the future of concrete cutting in Jacksonville looks promising. The emergence of diamond wire cutting, robotic concrete cutting, and laser-guided cutting methods brings numerous benefits to the construction industry. These advancements improve efficiency, safety, precision, and cost-effectiveness, making them essential tools for future projects in Jacksonville.

To learn more about concrete cutting technology and how it can benefit your construction projects, contact Urban Edge Concrete at (904) 867 8670 or visit https://urbanedgeconcrete.com/.

Remember, staying updated with the latest technology trends is crucial for staying ahead in the construction industry. Embracing the future of concrete cutting technology will undoubtedly lead to successful and innovative projects in Jacksonville.